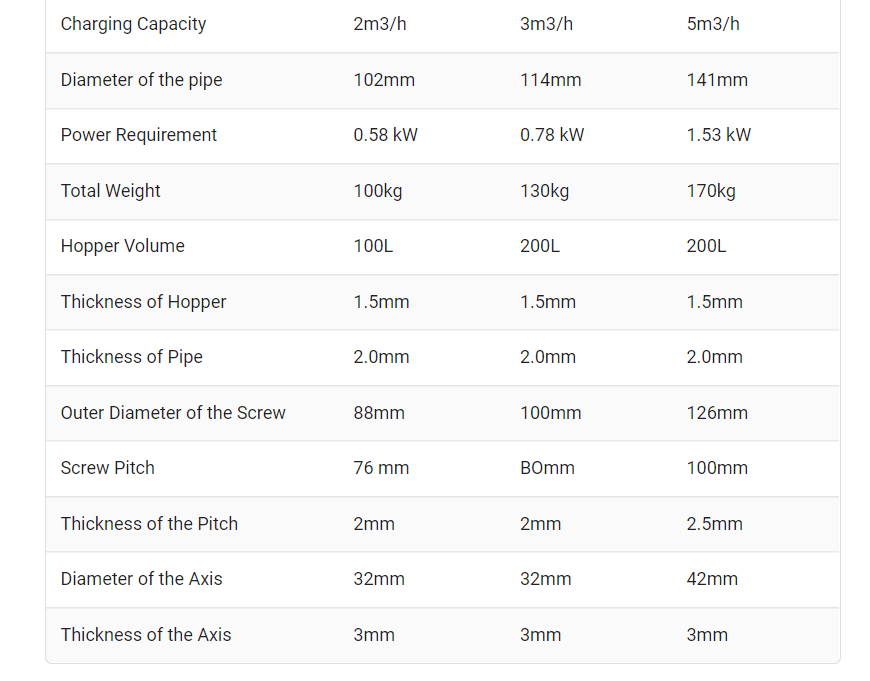

Screw Conveyors are designed to transport various loose, powdery, fine-grained, and dusty materials. Screw conveyors can effectively transport a wide range of loose products over small distances generally to elevate products to reach the top of a product metering system of a packaging system. Such sealed machines convey small-sized or finegrained materials easily, under the action of a rotation screw mechanism, inside an inclined steel pipe. The conveyor can be used as a separate unit as well as a part of a production or a packaging line. The machine is suitable for use in food, chemical, construction. and agro-industries. For food industries, the build material is SS304 stainless steel. These conveyors can be customized for height, bin/hopper size, or any other specialized parameters. Please contact us for customized inclined screw conveyors of any size and requirement.